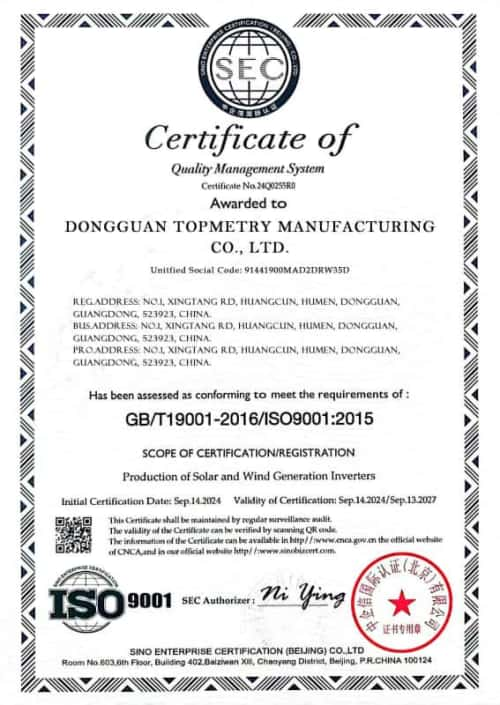

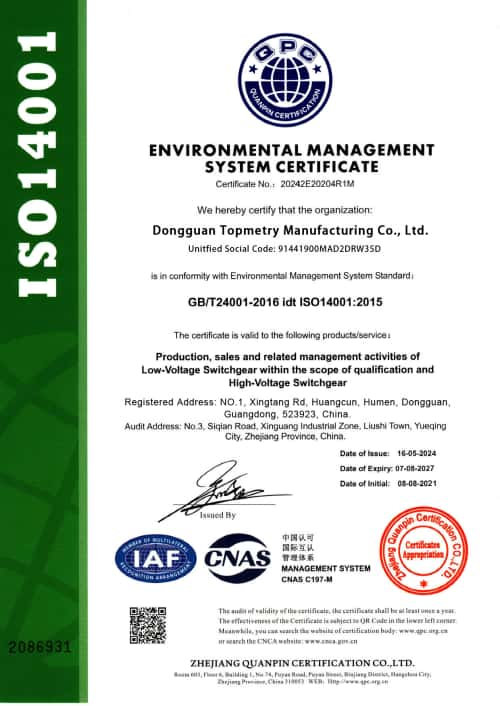

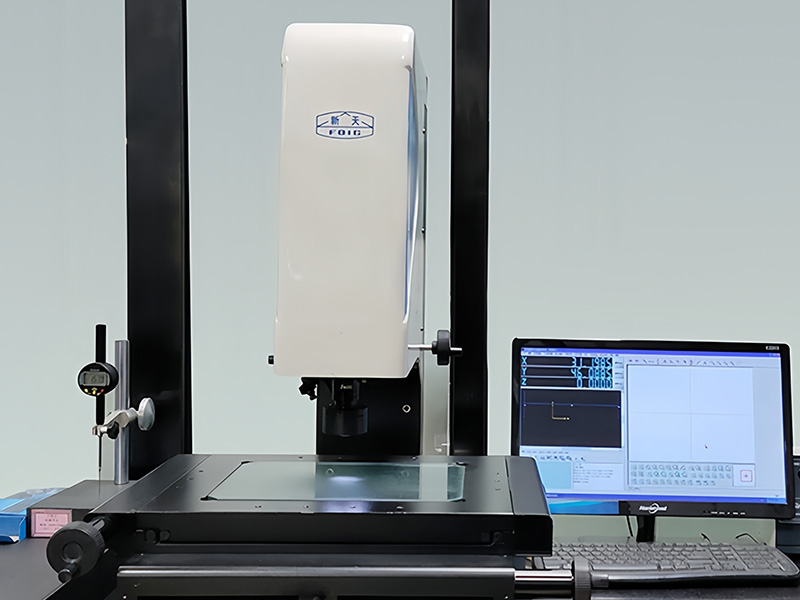

Quality Assurance

We help innovators transform their ideas into real parts quickly with our cost-effective, high-quality custom manufacturing services.

Get Your Quality

Parts Now

Let us help you get your parts get made at quality, on time, and within budget.

You will get quotation or reply for your project within 24 hours.