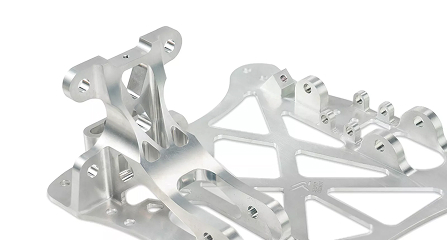

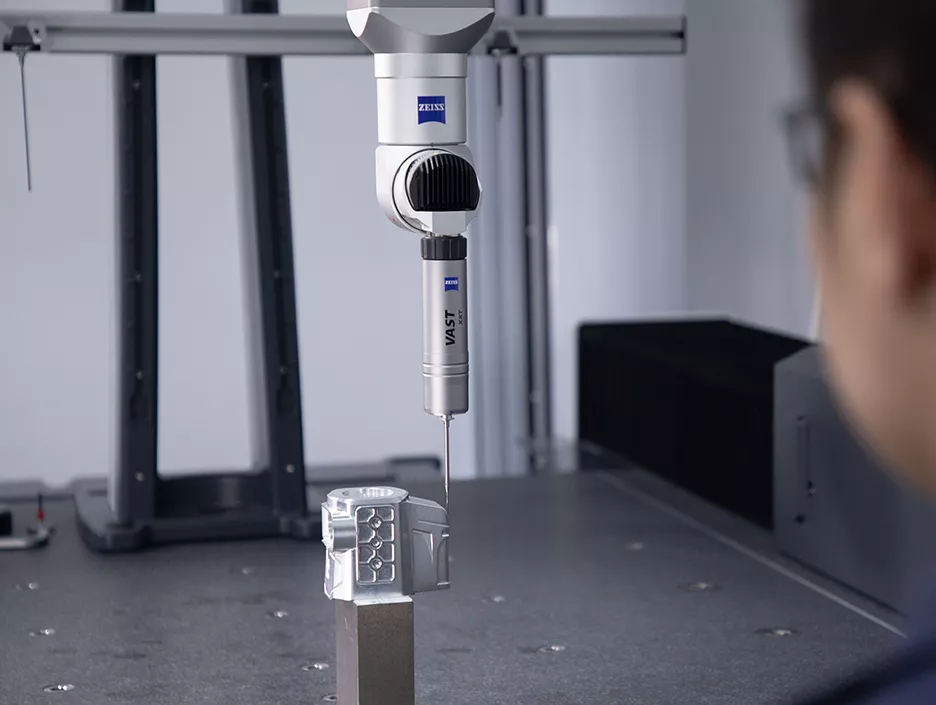

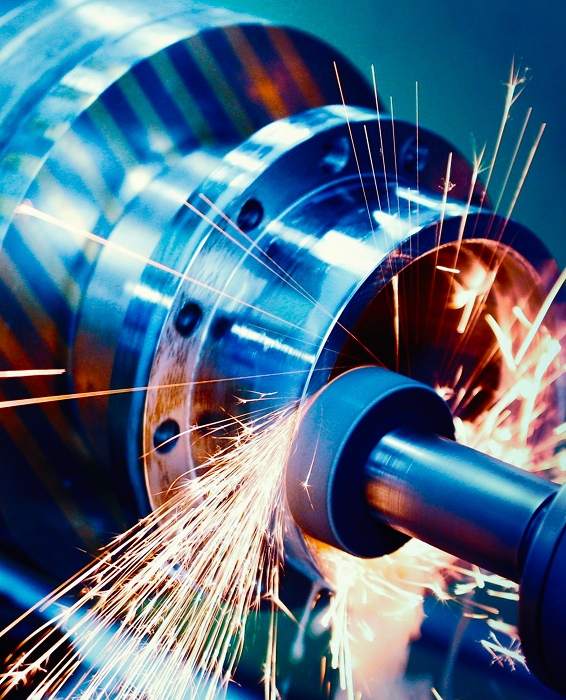

At Topmetry, we can machine parts from nearly any commercially available solid material. Whether you’re working with common metals or advanced engineering plastics, our CNC facilities are equipped to handle your custom prototyping or production needs.

We support both customer-supplied materials and special requests. If you require a specific grade or material not stocked in-house, we’re happy to source it or machine from the material you provide.

From aerospace aluminum to medical-grade titanium, and from high-impact plastics to thermally conductive copper, we offer a wide range of options to suit your mechanical, thermal, and cosmetic requirements.